- Accueil

- filet de plot

- Modeling, analysis, and multi-objective optimization of cold extrusion process of clutch outer gear hub using response surface method and meta-heuristic approaches

Modeling, analysis, and multi-objective optimization of cold extrusion process of clutch outer gear hub using response surface method and meta-heuristic approaches

4.6 (507) · € 15.50 · En Stock

Modeling and optimization of cold extrusion process by using response surface methodology and metaheuristic approaches

Selected fresh publications (June-August 2021) on gear manufacturing and related subjects

Modeling, analysis, and multi-objective optimization of cold extrusion process of clutch outer gear hub using response surface method and meta-heuristic approaches

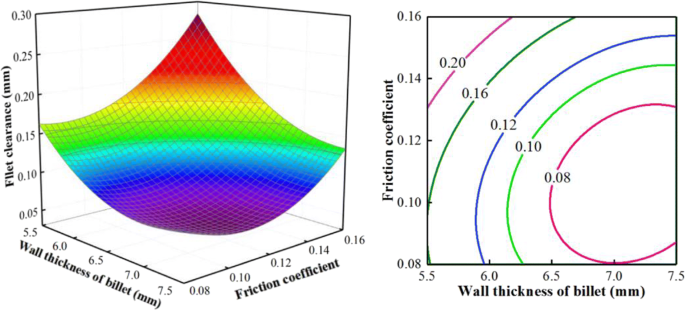

Numerical simulation and experimental study on cold extrusion process for clutch outer gear hub with inner tooth shapes

PDF) Numerical simulation and experimental study on cold extrusion process for clutch outer gear hub with inner tooth shapes

Energies, Free Full-Text

Energies, Free Full-Text

Performance optimization of a flexible manufacturing system using simulation: the Taguchi method versus OptQuest - Abdessalem Jerbi, Achraf Ammar, Mohamed Krid, Bashir Salah, 2019

Multi-objective shape optimization of large strain 3D helical structures for mechanical metamaterials - ScienceDirect

Schematic representation of twist extrusion process

Zuofa LIU, Doctor of Engineering, Chongqing University, Chongqing, CQU, School of Material Science and Engineering

Multi-objective robust optimization of foam-filled double-hexagonal crash box using Taguchi-grey relational analysis - Feng Xiong, Zhanfei Wang, Dengfeng Wang, Longbo Ji, Hang Wu, Xihong Zou, 2023

Machines, Free Full-Text