Fiberlogy ASA Filament - UV Resistant 3D Printing Filament – Narrow Path 3D

4.7 (255) · € 15.50 · En Stock

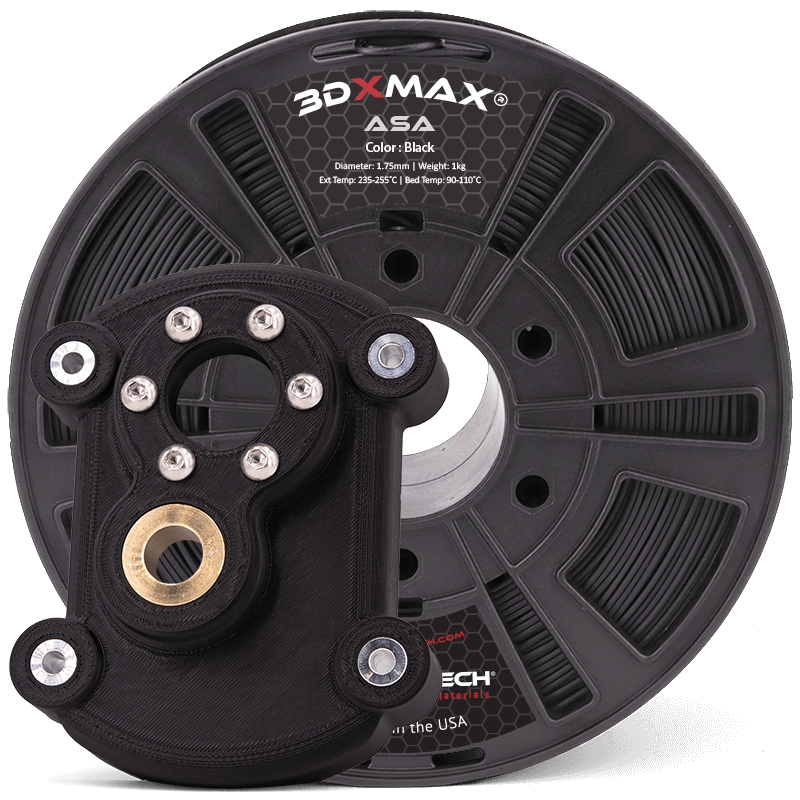

ASA: UV resistant 3D printer material with a subtle matte finish. Perfectly suited for prints that will be exposed to outdoor conditions and the elements, where durability is also a must. Finished stable prints will have resistance to temperatures up to 201F (94°C). ASA makes prints with structural integrity and durability, and a subtle matte finish making prints look polished and professional without the added processing time.

Key Features:

FIberlogy ASA is a highly UV ray resistant printing material with a subtle matte finish

Perfectly suited for prints that will be exposed to outdoor conditions and the elements, where durability is also a must

Finished stable prints will have resistance to temperatures up to 201F (94°C)

ASA gives prints more than structural integrity and durability with a subtle matte finish making prints look polished and professional without the added processing time (can be post-processed mechanically and chemically if desired)

Engineered and created in Poland using highly specialized machinery and carefully selected raw materials

Samples Collection:

You can also order an ASA sample to test from our Samples Collection ; create a custom sample pack to compare different options to find the exact right material for your project.

Durability for Years

Thanks to its resistance to UV radiation, high temperatures and humidity, Fiberlogy ASA is the perfect choice for all 3D printing applications that will be exposed to weather conditions (automotive, maritime, aerospace end-use parts and their prototypes).

High mechanical and thermal resistance (up to 94°C) and ease of printing make this material a great replacement for ABS, making it a popular choice in the automotive industry, and in the manufacturing of everyday items.

ASA (acrylonitrile-styrene-acrylate), due to its significantly lower shrinkage than ABS, does not require a heated chamber to ensure a successful print.

ASA also gives off much less annoying odors. Less shrinkage and good adhesion prevent the model from curling and cracking and ensure high stability of the print dimensions.

The finished model made with Fiberlogy ASA can be smoothed by exposure to acetone. The material is suitable for sanding and painting. It can also be glued with acetone.

Printing Ideas and Applications:

Automotive/Marine/Aerospace: car and motorcycle parts, accessories, substitutes; end-use parts and prototyping; exterior elements, decals.

Sport: guards, sport accessories, spare parts;

Homes and Garden: decorations, equipment, tools, everyday objects;

Electronics: sensor and microcontroller housings.

How to Print:

The following parameters are only suggested print settings for this material. To ensure the best print quality, it is necessary to choose the appropriate settings for a specific printer and printing conditions.

Nozzle Temperature

255-270°C

Bed Temperature

90-110°C

Closed chamber

not required, but highly recommended

Fan

0-25%

Flowrate

90-100%

Printing Speed

< 100 mm/s

Surface

glass, kapton tape, ABS juice

Retraction (direct)

1-2 mm

Retraction (bowden)

4-6 mm

Retraction Speed

20-45 mm/s

Notes

When printing without a heated chamber, it is recommended to avoid exposing the model to gusts of wind/drafts

You can find more detailed recommended print settings for all Fiberlogy Filaments in this article.

TDS and MSDS:

Click Here to View the TDS (Technical Data Sheet)

Click Here to View the MSDS (Material Safety Data Sheet)

Fiberlogy 3D Filaments US – Narrow Path 3D

How to Print Fiberlogy Filaments: Print Settings, Info, and Notes

Overture ASA 3D Printer Filament 1.75mm – Overture 3D

Buy Filament PLA 1,75mm 0,75kg - black Botland - Robotic Shop

All Samples – Narrow Path 3D

Filament Fiberlogy ASA 1,75mm 0,75kg - Yellow Botland - Robotic Shop

ANYCUBIC ASA Filament 1.75mm, Weather & Heat Resistant

Products – Narrow Path 3D

High quality filament with UV and weather resistance in Onyx colour

Fiberlogy ASA Onyx, 1.75mm / 750g

Advanced guide to printing ASA Filament